Current location: Xiamen Lingzhao > Product > Bently

Current location: Xiamen Lingzhao > Product > Bently

Product introduction

Product introduction

Bently Nevada The 330106-05-30-10-02-05 is an 8mm reverse-mount eddy-current pro

News

News

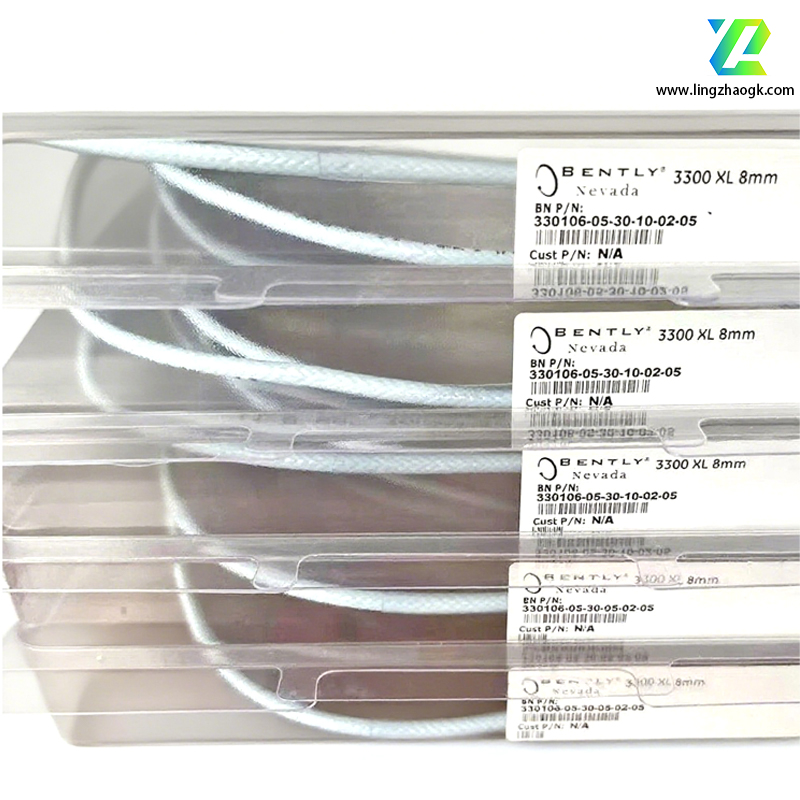

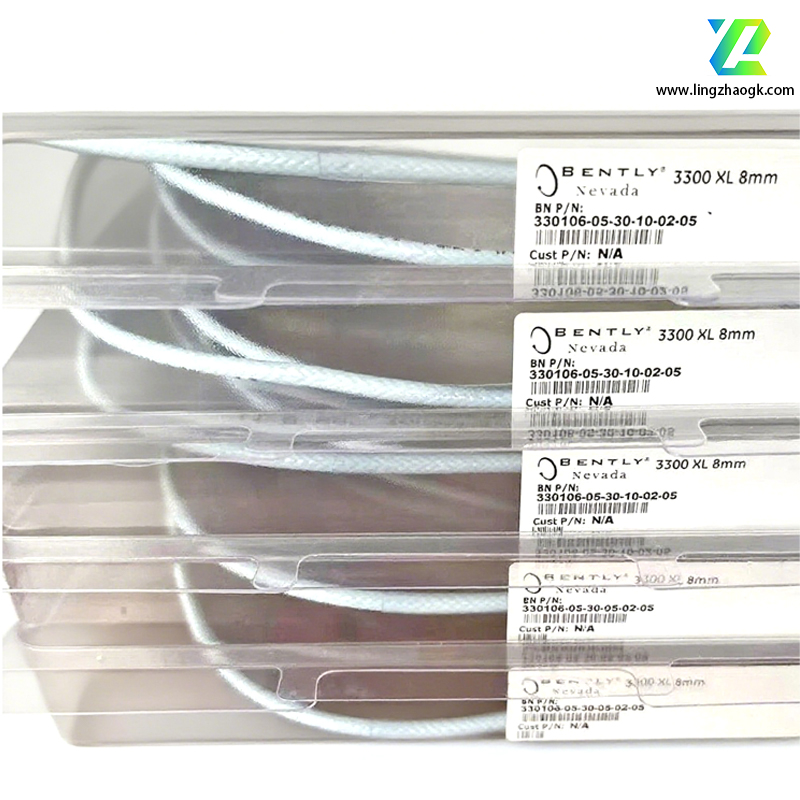

Bently Nevada The 330106-05-30-10-02-05 is an 8mm reverse-mount eddy-current probe in the 3300 XL series, designed for high-precision condition monitoring of rotating machinery. The following is its core information: ### I. Core Functions and Technical Specifications 1. **Measurement Capabilities** - **Parameter Coverage**: Simultaneously monitors key parameters such as shaft vibration (peak-to-peak), shaft displacement, key phase, and speed, making it suitable for dynamic and static measurements of oil-film bearings. - **Linear Range**: 2mm (80 mils), starting at 0.25mm (10 mils) from the target surface, with an output signal range of approximately -1 to -17 Vdc. Sensitivity: 7.87 V/mm (200 mV/mil) ±5%, with linearity better than ±1% of full scale, meeting the stringent API 670 standard for industrial vibration monitoring. 2. Physical Characteristics: Mounting Thread: M10 x 1 standard thread, compatible with universal mounting brackets, supports reverse mounting for compact spaces. Cable Configuration: 1.0 m (3.3 ft) total length, featuring a micro ClickLoc coaxial connector with a 330 N (75 lbf) tensile strength, ensuring a reliable, long-term connection. - **Material and Protection**: The stainless steel housing (AISI 303/304) with Viton® O-rings achieves IP67 protection, ensuring stable operation in environments with dust, water spray, and short-term submersion (1 meter depth for 30 minutes). 3. **Environmental Adaptability** - **Temperature Range**: Operating temperature: -35°C to +85°C, storage temperature: -52°C to +105°C, meeting the requirements of high-temperature industrial scenarios (such as gas turbines). - **Anti-Interference Design**: Triple anti-interference mechanisms, including shielded cable differential transmission, adaptive digital filtering algorithms, and a fully sealed structure, provide protection against radio frequency interference (RFI/EMI) and electromagnetic pulses. ### II. Product Features and Certifications 1. **Enhanced Reliability** - **Structural Innovation**: Patented TipLoc™ injection molding technology strengthens the connection between the probe tip and the probe body, preventing mechanical fatigue from high-frequency vibration. - **Intelligent Diagnosis**: Built-in coil impedance monitoring circuitry provides real-time detection of probe aging, cable breakage, or gap violations, outputting HART protocol alarm signals. 2. **Safety and Compliance** - **Certification Coverage**: CSA, ATEX, and IECEx certified, suitable for use in explosive gas environments (Class I Div 1), meeting the explosion-proof requirements of high-risk applications such as petrochemicals and mining. Compatibility: Fully compatible with the 3300 XL Series Proximitor Sensor (e.g., 330180-50-00) and 3500 Series Monitoring Modules (e.g., 3500/42M), supporting plug-and-play configuration. 3. Installation Flexibility: Modular Expansion: A variety of extension cables (e.g., 330130-040-00) are available, allowing the system to be extended to 5- and 9-meter lengths, meeting long-distance signal transmission requirements. Mounting: DIN rail or panel mounting is supported. The electrical isolation design eliminates the need for additional insulation panels, reducing installation complexity. ### III. Typical Application Scenarios 1. **Industrial Equipment Monitoring** - **Rotating Machinery**: Steam turbines, compressors, fans, pumps, gearboxes, etc., for early detection of faults such as imbalance, misalignment, and bearing wear. - **Critical Infrastructure**: Generators in the power industry, rolling mills in the metallurgical industry, and reactor drives in the petrochemical industry. 2. **Special Environment Adaptation** - **High-Temperature Scenarios**: Its high-temperature ferrite core and air/ceramic dual-insulation package maintain ±1% accuracy at short-term temperatures up to 350°C. - **Harsh Operating Conditions**: Its IP67 protection rating makes it suitable for use in complex environments such as dusty workshops, open-pit mines, and offshore platforms. ### IV. Selection and Configuration Recommendations - **Model Explanation**: In the 330106-05-30-10-02-05, "10" represents a total length of 1.0 meter, "02" corresponds to the micro ClickLoc connector, and "05" indicates the multi-certification configuration. - **System Integration**: It is recommended to pair this probe with a 3300 XL Proximitor Sensor (such as the 330180-50-00) and a 3500/42M Monitoring Module for real-time analysis of vibration amplitude, phase, and spectrum. - **Maintenance Tip**: Regularly verify probe sensitivity using a 9110D Portable Vibration Calibrator to ensure long-term measurement accuracy. With its high accuracy, reliability, and adaptability to harsh environments, this probe is a core component for predictive maintenance of industrial equipment, helping users reduce the risk of downtime and optimize operational costs.

Bently Nevada 330106-05-30-10-02-05 Reverse Mount Eddy Current Probe

Bently Nevada 330106-05-30-10-02-05 Reverse Mount Eddy Current Probe

We have the discontinued spare parts you urgently need!

A complete range of models and sufficient stock! Spot goods will be shipped immediately, and the price is favorable!

Sales Manager: Liu Jing

Email: 3918466031@qq.com 丨 Phone/WeChat: +86 13328402352/13328402352

Leave a message online

Email: 3918466031@qq.com

Hotline: 13328402352

Address: Phase III of Software Park, Jimei District, Xiamen City, Fujian Province, China

Copyright © 2025 Xiamen Lingzhao E-Commerce Co., Ltd. All rights reserved

About

Message

Message

Connect

Connect

Product

ABB

ABB

Allen Bradley

Allen Bradley

AI-TEK

AI-TEK

Bently

Bently

Berger Lahr

Berger Lahr

Industry application

Maritime transport

Maritime transport

sewage treatment

sewage treatment

AI

AI

Automobile Manufacturing

Automobile Manufacturing